Construction vehicles and machinery pose new challenges for manufacturers, with increased diversity and performance capabilities required. Find the ideal solution for your needs in our specialized range of actuators for construction applications.

Purpose-Built Linear Motion for Construction.

Designed to deliver smooth and reliable movement in any environment for years to come.

2.41%

Average YoY Cost Reduction99.8%

Perfect QC Pass Rate100%

Powered By Renewable EnergyWe're More than a Supplier: Adding Value Beyond the Product.

With an unwavering commitment to mutual success, we're a flexible partner that adds value at every step along the component lifecycle.

Consistently High Product Quality

Get ultra-low product failure rates with a quality control regime that's reliable, stringent, adaptive and systematic.

Progressive Automations is ISO9001.2015 Certified

Get quality you can trust. Work with a partner that's truly committed to continuous improvement.

Flexible Pricing with Pass-Through Cost Reductions

Unlock savings with ramp-up friendly, inflation-resistant pricing, where scale-related savings pass directly on to you.

We Deliver on Time, Every Time.

Even with supply chain challenges becoming more common, we've maintained a 98% on-time shipment rate since 2017.

Zero Lead Times & Unparalleled Flexibility with Smart Logistics

Avoid costly air freight and production delays. We get custom units to your dock in days, not months.

Linear actuator are essential for various systems in compact wheel loaders, ensuring efficient and accurate movement. This precision enhances the overall operation of construction equipment, facilitating seamless performance in diverse construction tasks.

Electric linear actuators elevate skid-steer functionality by providing precise control, automation, and robust safety features. They streamline operations by adjusting attachments, controlling movement, and integrating with automated systems, ensuring efficient and safe material handling in diverse environments.

Electric linear actuators significantly improve site dumpers by facilitating precise control over tilt and elevation adjustments, gate operations, and material discharge. Their integration streamlines unloading processes, enhances operational reliability, and reduces manual labor, promoting safer and more efficient construction operations.

Electric linear actuators enhance compact excavators by providing precise control and advanced automation. They adjust roof hatches, cabin seats, and bucket positions, control auxiliary hydraulic functions, and integrate with automated systems, streamlining operations and boosting productivity and safety while reducing manual labor.

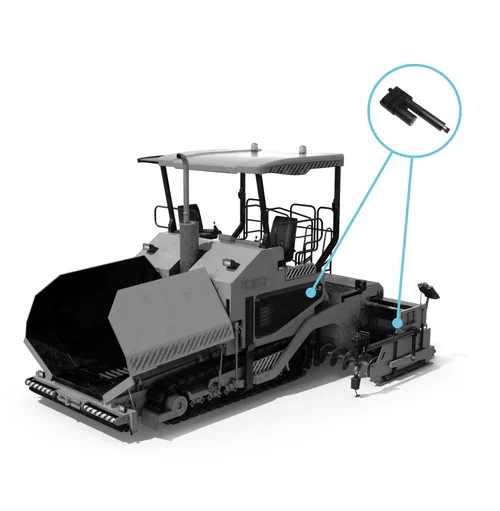

Pavers use electric linear actuators to adjust screed height, control flow gates, and distribute materials evenly. This precise control and automation improve operational efficiency and safety in paving projects, contributing to smoother road surfaces and enhanced infrastructure quality.

Concrete buggys are wheeled vehicles designed to transport and distribute concrete across construction sites. They feature a bucket or hopper for holding concrete and are equipped with electric linear actuators, which provide precise control over movements such as tilting the bucket and controlling discharge gates. This enhances efficiency and safety in concrete placement, contributing to smoother construction operations.

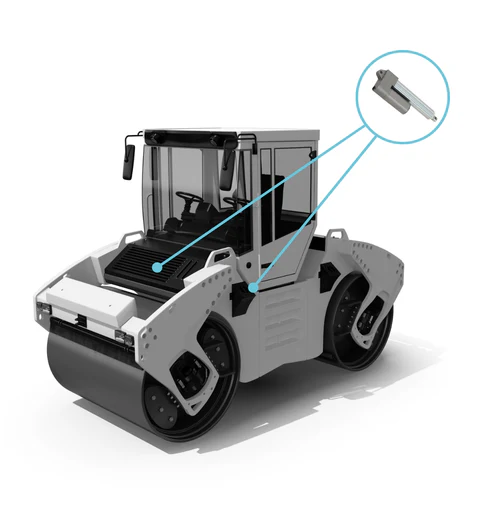

Rollers are heavy machines with large drums used to compress and flatten materials like soil, gravel, and asphalt. They eliminate air voids and create dense surfaces, crucial for stable roads and structures. Rollers come in various sizes and configurations, equipped with features like vibratory motion for efficient compaction.

“There was nothing in the way of a camper that went on like a Tacoma, a Chevy Colorado, a Nissan Frontier, a Ford Ranger,” Wise said. “Anything that was available had the cantilevered bed that went over the top of it, and it was canvas. So, we came up with a hard-sided, folding camper. It’s all fiberglass and aluminum. It’s completely waterproof and it comes in at less than 1,200 pounds."

Rick Wise and Joe Orr

Co-founders of Cube Series

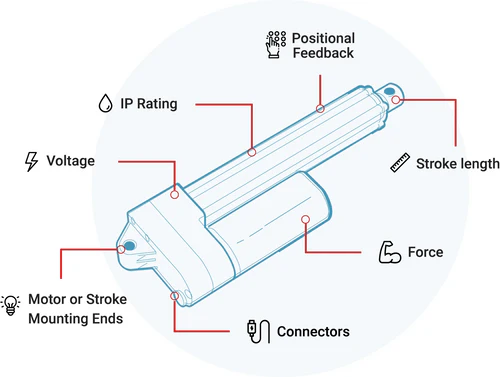

Custom Linear Motion for Construction

Actuator Customization

Transform your projects with actuators built for your unique challenges. Whether you're transitioning from hydraulics or facing issues like water ingress, we understand that every application is unique.

Our engineers help you craft solutions that fit your exact specifications, with flexible minimum quantities, turning complex requirements into precise, efficient designs.

As your needs evolve, so do our solutions - we're here for the long haul, and you're gaining a partner dedicated to your success.

Case Studies

Make The Project Of Your Dream

Boat Engine Hatch

By using quality custom linear actuators and advanced control systems for synchronization, Progressive Automations offers convenient, reliable, and user-friendly automation solutions that enable customers to protect their engine hatches through automated hatch covers. In this case study, we will cover the process, challenges, and solutions involved in bringing automated hatch covers to life for boats, yachts, and other sea vessels.

Make The Project Of Your Dream

Cube Series Camper

By using linear actuators and ultra-lightweight folding technology, Cube Series RV aims to offer lightweight, compact, and convenient campers that are also suitable for compact pickups without sacrificing durability. In this case study, we will cover the process, challenges, and solutions the team at Cube Series RV had faced in bringing their Cube Series Camper to life.

Make The Project Of Your Dream

Boat Engine Hatch

By using quality custom linear actuators and advanced control systems for synchronization, Progressive Automations offers convenient, reliable, and user-friendly automation solutions that enable customers to protect their engine hatches through automated hatch covers. In this case study, we will cover the process, challenges, and solutions involved in bringing automated hatch covers to life for boats, yachts, and other sea vessels.

Make The Project Of Your Dream

Cube Series Camper

By using linear actuators and ultra-lightweight folding technology, Cube Series RV aims to offer lightweight, compact, and convenient campers that are also suitable for compact pickups without sacrificing durability. In this case study, we will cover the process, challenges, and solutions the team at Cube Series RV had faced in bringing their Cube Series Camper to life.

Make The Project Of Your Dream

Boat Engine Hatch

By using quality custom linear actuators and advanced control systems for synchronization, Progressive Automations offers convenient, reliable, and user-friendly automation solutions that enable customers to protect their engine hatches through automated hatch covers. In this case study, we will cover the process, challenges, and solutions involved in bringing automated hatch covers to life for boats, yachts, and other sea vessels.

DISCOVER MORE

Article de blog

Electric Actuators: Revolutionizing Industrial Automation Beyond Hydraulic Cylinders

Blog Post

Download The Testing Guide

This guide will outline essential steps and the process of evaluating a sample actuator. We include a checklist to ensure all the requirements are met.

Blog Post

Top 10 Questions We Get from Our OEM Customers

You will find useful FAQ from OEM Customer as for your search for a parts supplier of electric linear actuators.

Application

Compact Wheel Loaders

Linear actuator are essential for various systems in compact wheel loaders, ensuring efficient and accurate movement. This precision enhances the overall operation of construction equipment, facilitating seamless performance in diverse construction tasks.

Challenges

Compact wheel loaders with linear actuators face issues such as mechanical play, wear and tear, motor noise, and compatibility with existing systems. These challenges affect positioning accuracy, durability, operator comfort, and system integration.

Solutions

Advanced feedback systems and closed-loop control algorithms improve precision, while reinforced alloys and protective coatings enhance durability. Vibration damping mechanisms reduce noise, and compatibility with industry-standard protocols simplifies integration.

Benefits

These solutions ensure precise positioning, long-term reliability, improved operator comfort, and seamless integration, ultimately boosting productivity and operational efficiency in demanding environments.

Compact Wheel Loaders

Seat Adjustment

Model

PA-04 Linear Actuator

Function

Electric linear actuators adjust the operator’s seat position for improved comfort and ergonomics.

Benefits

Reduce operator fatigue during extended use, leading to better productivity and job satisfaction. Customizable seat positions accommodate operators of different sizes and preferences, enhancing overall comfort and well-being.

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our line-up.

It is popular within the Mobile Machinery and Farming industries.

Key Features

- Versatile Force Rating

- Low Noise

- High Speed

- Maintenance Free

- Excellent Price/Performance Ratio

- IP66 Water Protection

Request Custom Specs

Application

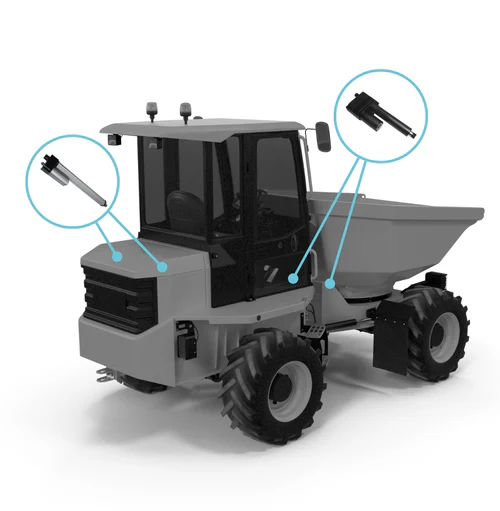

Site Dumpers

Electric linear actuators significantly improve site dumpers by facilitating precise control over tilt and elevation adjustments, gate operations, and material discharge. Their integration streamlines unloading processes, enhances operational reliability, and reduces manual labor, promoting safer and more efficient construction operations.

Challenges

Challenges in site dumper operation encompass heavy load handling, harsh environmental conditions, vibration and shock resistance, control precision, energy efficiency, and reliability. Addressing these hurdles is crucial for ensuring optimal performance and durability in construction and material handling tasks.

Solutions

Solutions for site dumper challenges involve robust construction using high-strength materials, sealed designs with high IP ratings, integration of shock-absorbing mechanisms and vibration-dampening materials, implementation of high-resolution position feedback systems, energy-efficient designs with regenerative braking, and proactive maintenance strategies for enhanced reliability and durability in diverse operating conditions.

Benefits

Electric linear actuators revolutionize site dumpers by providing precise control over dump body adjustments, automating dumping processes, and enhancing safety features. Their reliability, energy efficiency, low maintenance requirements, and quiet operation contribute to optimized construction operations, ensuring smoother and more efficient material handling.

Site Dumpers

Automated Hood

Model

PA-10 Linear Actuator

Function

Electric linear actuators adjust the hood's opening angle based on the operator's controls.

Benefits

Allows for fast and convenient access to the engine compartment for repair and maintenance servicing.

PA-10-HALL Linear Actuator

The PA-10 is a highly efficient waterproof actuator designed for a wide range of applications, including mobile machinery equipment.

Key Features

- Hall Sensor Customizations

- Compact Size

- High Performance/Size Ratio

- Maintenance Free

- Low Noise

- IP68M Waterproof Protection

Site Dumpers

Automating Unloading Processes

Model

PA-17 Linear Actuator

Function

Electric linear actuators adjust the tilt and positioning of the load according to the controls of the operator.

Benefits

They promote safer and more efficient construction operations by streamlining the unloading processes, enhancing operational reliability, and reducing manual labor.

PA-17 Linear Actuator

The PA-17 Heavy Duty Linear Actuator offers high force ratings and durable construction at an excellent price point.

Key Features

- High Load Capacity

- Protection/Safety Features

- Maintenance Free

- Durable Construction

- IP65 Water Protection

- Excellent Price/Performance Ratio

Request Custom Specs

Request Custom Specs

Application

Pavers

Pavers use electric linear actuators to adjust screed height, control flow gates, and distribute materials evenly. This precise control and automation improve operational efficiency and safety in paving projects, contributing to smoother road surfaces and enhanced infrastructure quality.

Challenges

Challenges for pavers with electric linear actuators include precision control, load handling under varying conditions, environmental resilience, vibration resistance, energy efficiency, reliability, integration compatibility, and cost-effectiveness. Overcoming these hurdles demands advanced technology, robust design, and strategic solutions tailored to customer needs and industry standards.

Solutions

Solutions for pavers with electric linear actuators involve advanced control algorithms for precise positioning, robust designs to handle varying loads, IP-rated enclosures for environmental protection, shock-absorbing mechanisms for vibration resistance, energy-efficient motors, quality materials for durability, standard interfaces for easy integration, and diverse actuator models to balance performance with cost-effectiveness. These strategies ensure reliable, efficient, and seamless operation in paving applications.

Benefits

Electric linear actuators provide numerous benefits for pavers. They offer precise control over components like the screed, ensuring uniform paving and consistent quality. Automation streamlines operations, enhancing productivity and safety. With robust construction and low maintenance needs, they support reliable and durable paving. Additionally, their energy efficiency, quiet operation, and seamless integration contribute to sustainable and versatile paving practices.

Pavers

Controlled Pavement Thickness Adjustment

Model

PA-13 Linear Actuator

Function

Electric linear actuators enable precise adjustment of pavement thickness during paving operations. By controlling the extension or retraction of the actuator, operators can ensure uniform pavement thickness across the entire surface. This precision helps in meeting project specifications and quality standards, ultimately enhancing the durability and longevity of the pavement.

Benefits

Enhanced Quality Control: Accurate adjustment ensures uniform pavement thickness, reducing the likelihood of uneven surfaces or weak spots. Improved Durability: Consistent thickness contributes to the overall strength and resilience of the pavement, minimizing the risk of premature wear or structural issues.

PA-13 Linear Actuator

The PA-13 High Force Industrial Linear Actuator is one of the strongest units in our line-up.

Key Features

- High Load Capacity

- Protection/Safety Features

- Maintenance Free

- Durable Construction

- IP66 Water Protection

Pavers

Auger Height Control

Model

PA-13 Linear Actuator

Function

Electric linear actuators control the height of the auger assembly, which is responsible for feeding asphalt or concrete material into the paving machine. Proper adjustment of the auger height ensures consistent material delivery, preventing overloading or underfeeding during the paving process.

Benefits

Accurate auger height control ensures uniform material distribution, preventing pavement inconsistencies, while automated adjustment by electric actuators enhances operator safety by reducing manual intervention and injury risk.

PA-13 Linear Actuator

The PA-13 High Force Industrial Linear Actuator is one of the strongest units in our line-up.

Key Features

- High Load Capacity

- Protection/Safety Features

- Maintenance Free

- Durable Construction

- IP66 Water Protection

Request Custom Specs

Request Custom Specs

Application

Concrete Buggys

Concrete buggys are wheeled vehicles designed to transport and distribute concrete across construction sites. They feature a bucket or hopper for holding concrete and are equipped with electric linear actuators, which provide precise control over movements such as tilting the bucket and controlling discharge gates. This enhances efficiency and safety in concrete placement, contributing to smoother construction operations.

Challenges

Challenges for concrete buggys with electric linear actuators include achieving precise control in concrete pouring, handling varying load conditions, and ensuring resilience to harsh environmental factors. Additionally, addressing vibration and shock resistance, energy efficiency, integration, reliability, and cost considerations are crucial for optimal performance and longevity.

Solutions

Solutions for concrete buggys with electric linear actuators involve implementing advanced control algorithms and feedback systems for precise control. Designing robust actuators with overload protection ensures safe load handling, while selecting materials and coatings for environmental resilience enhances durability. Incorporating shock-absorbing mechanisms and regenerative braking improves stability and energy efficiency. Compatibility with control systems and offering diverse actuator models addresses integration and cost considerations.

Benefits

Electric linear actuators revolutionize concrete buggys by providing precise control, automation, and durability. Their ability to adjust tilt, manage discharge gates, and ensure smooth pouring enhances operational efficiency and safety. With energy efficiency and low maintenance, they offer cost-effective solutions for construction projects.

Concrete Buggys

Tilt and Dump Control

Model

PA-13 Linear Actuator

Function

Electric linear actuators manage the tilt and dumping actions of the buggy, allowing for controlled discharge of concrete.

Benefits

Actuators ensure smooth, consistent concrete dumping, minimizing waste and spillage. Enhanced control improves placement precision and quality, while controlled dumping enhances safety by preventing sudden weight shifts and accidents.

PA-13 Linear Actuator

The PA-13 High Force Industrial Linear Actuator is one of the strongest units in our line-up.

Key Features

- High Load Capacity

- Protection/Safety Features

- Maintenance Free

- Durable Construction

- IP66 Water Protection

Concrete Buggys

Steering Adjustments

Model

PA-01 Linear Actuator

Function

Electric linear actuators assist in making precise steering adjustments to navigate the concrete buggy.

Benefits

Fine steering adjustments enhance the buggy's maneuverability in tight spaces and complex job sites. Improved precision ensures accurate, safe navigation, reducing collisions. This control boosts operator efficiency and safety during operations.

PA-01 Linear Actuator

Compact in size with medium force capabilities, this actuator has a low current draw ideal for power efficiency.

Key Features

- Hall Sensor Customizations

- Compact Size

- High Performance/Size Ratio

- Maintenance Free

- Low Noise

- IP65 Water Protection

Request Custom Specs

Request Custom Specs

Application

Rollers

Rollers are heavy machines with large drums used to compress and flatten materials like soil, gravel, and asphalt. They eliminate air voids and create dense surfaces, crucial for stable roads and structures. Rollers come in various sizes and configurations, equipped with features like vibratory motion for efficient compaction.

Challenges

Electric linear actuators play a crucial role in enhancing the functionality of rollers, offering precise control, efficient power usage, and durability in challenging environments. Challenges include maintaining precision, power efficiency, and durability, while solutions involve advanced control systems, energy-efficient designs, and robust construction materials.

Solutions

Solutions for addressing challenges with electric linear actuators in rollers include implementing advanced control systems for precision, utilizing energy-efficient designs and regenerative braking systems to optimize power usage, designing actuators with high Ingress Protection (IP) ratings and robust construction materials for durability, ensuring seamless integration with existing systems, and incorporating noise and vibration dampening features for improved operational comfort.

Benefits

Electric linear actuators for rollers offer precise control, automation capabilities, and energy efficiency, enhancing compaction quality while reducing operational costs. Their quiet operation, robust construction, and safety features ensure reliable performance, while ease of installation and customization options increase versatility and cost-effectiveness, making them essential components for construction projects.

Rollers

Cabin and Seat Adjustments

Model

PA-09 Linear Actuator

Function

Linear actuators allow for smooth and precise adjustment of the cabin seat's height.

Benefits

Allows users to comfortably adjust the sitting position according to their personal preference, enhancing convenience and ergonomics.

PA-09 Linear Actuator

The PA-09 offers durability and high force capabilities in a compact-sized linear actuator.

Key Features

- Compact Size

- Low Noise

- High Force

- Maintenance Free

- Excellent Price/Performance Ratio

Rollers

Automated Hood

Model

PA-09 Linear Actuator

Function

Electric linear actuators adjust the hood's opening angle based on the operator's controls.

Benefits

Allows for fast and convenient access to the engine compartment for repair and maintenance servicing.

PA-09 Linear Actuator

The PA-09 offers durability and high force capabilities in a compact-sized linear actuator.

Key Features

- Compact Size

- Low Noise

- High Force

- Maintenance Free

- Excellent Price/Performance Ratio

Request Custom Specs

Request Custom Specs

Application

Skid-Steers

Electric linear actuators elevate skid-steer functionality by providing precise control, automation, and robust safety features. They streamline operations by adjusting attachments, controlling movement, and integrating with automated systems, ensuring efficient and safe material handling in diverse environments.

Challenges

Challenges arise when integrating electric linear actuators into skid-steers. Precision control demands accuracy amidst complex tasks. Load handling must accommodate varying loads without compromising safety. Energy efficiency is crucial for prolonged operation. Environmental factors like dust and moisture pose durability challenges. Integration with existing systems requires compatibility, while noise and vibration levels need mitigation.

Solutions

To address challenges integrating electric linear actuators into skid-steers, solutions include advanced control algorithms for precision, robust designs with overload protection for load handling, energy-efficient systems with regenerative braking, corrosion-resistant materials for environmental resilience, standardized protocols for compatibility, noise-reducing designs, redundant safety features, and customizable options for scalability.

Benefits

Electric linear actuators offer precision, efficiency, and safety benefits for skid-steers. With accurate positioning, low power consumption, and robust construction, they enhance operational performance while minimizing maintenance needs. Their flexibility and cost-effectiveness make them indispensable components in modern skid-steer equipment.

Skid - Steers

Attachment Control

Model

PA-04 Linear Actuator

Function

Electric linear actuators precisely control the movement and positioning of various attachments, such as buckets, forks, grapples, and augers.

Benefits

This precision allows operators to perform tasks with greater accuracy, such as precise digging, lifting, and material handling, improving overall job quality and efficiency.

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our line-up.

It is popular within the Mobile Machinery and Farming industries.

Key Features

- Versatile Force Rating

- Low Noise

- High Speed

- Maintenance Free

- Excellent Price/Performance Ratio

- IP66 Water Protection

Skid-Steers

Cabin and Seat Adjustments

Model

PA-04 Linear Actuator

Function

Linear actuators allow for smooth and precise adjustment of the cabin seat's height.

Benefits

Allows users to comfortably adjust the sitting position according to their personal preference, enhancing convenience and ergonomics.

PA-04 Linear Actuator

The PA-04 is the most versatile linear actuator in our line-up.

It is popular within the Mobile Machinery and Farming industries.

Key Features

- Versatile Force Rating

- Low Noise

- High Speed

- Maintenance Free

- Excellent Price/Performance Ratio

- IP66 Water Protection

Request Custom Specs

Request Custom Specs

Application

Compact Excavators

Electric linear actuators enhance compact excavators by providing precise control and advanced automation. They adjust roof hatches, cabin seats, and bucket positions, control auxiliary hydraulic functions, and integrate with automated systems, streamlining operations and boosting productivity and safety while reducing manual labor.

Challenges

Ensuring durability in harsh environments, maintaining precision, integrating with existing systems, ensuring safety, handling heavy loads, reducing power consumption, achieving responsiveness, and managing costs are key challenges. Solutions include using robust materials, feedback mechanisms, flexible designs, safety features, energy-efficient motors, and advanced control algorithms.

Solutions

Use corrosion-resistant materials and high IP ratings for durability, feedback mechanisms for precision, and flexible designs for integration. Implement safety features, energy-efficient motors, and advanced control algorithms. Ensure actuators handle heavy loads, provide adjustable speeds, and use cost-effective, high-quality materials for affordability.

Benefits

Electric linear actuators provide precise control over boom, arm, and bucket positions, enhancing maneuverability and accuracy. They enable automation, reducing manual adjustments and integrating with control systems for seamless operation. Safety features like overload protection and emergency stops increase reliability, while their energy efficiency, low maintenance, and quiet operation improve overall performance.

Compact Excavators

Automated Roof Hatch

Model

PA-10 Linear Actuator

Function

Actuators enable adjustable positioning of the roof hatch to various angles.

Benefits

Users can set the roof angle according to preferences or environmental conditions for optimal ventilation, temperature regulation, and natural light.

PA-10 Linear Actuator

The PA-10 is a highly efficient waterproof actuator designed for a wide range of applications, including mobile machinery equipment.

Key Features

- Hall Sensor Customizations

- Compact Size

- High Performance/Size Ratio

- Maintenance Free

- Low Noise

- IP68M Waterproof Protection

Compact Excavators

Cabin and Seat Adjustments

Model

PA-17 Linear Actuator

Function

Linear actuators allow for smooth and precise adjustment of the cabin seat's height.

Benefits

Allows users to comfortably adjust the sitting position according to their personal preference, enhancing convenience and ergonomics.

PA-17 Linear Actuator

The PA-17 Heavy Duty Linear Actuator offers high force ratings and durable construction at an excellent price point.

Key Features

- High Load Capacity

- Protection/Safety Features

- Maintenance Free

- Durable Construction

- IP65 Water Protection

- Excellent Price/Performance Ratio